Hi there,

I usually update or post a new blog during weekends but this one gets me excited. This is about another electronic gadget I have which is a battery desulfator. For those of you who own a car, an inverter (from a solar panel system maybe), or just use lead-acid batteries for your power, machinery and electricity needs, well, you have to own this gadget.

A desulfator (or desulphator) is a device that restores capacity to lead-acid batteries, extending their effective life span. These devices are also known as battery re-conditioners. You see, lead-acid batteries, during use produces sulfate crystals on the battery plates as a product of chemical processes taking place for a battery to produce current at a certain voltage. Overtime, an excess accumulation of these crystals on the battery will shorten the battery life since it prevents the active parts of the battery to properly react with each other. Now, I'm not after the whole chemistry of how this happens exactly but for sure, this is a well known fact between chemistry and the science behind lead-acid batteries.

A desulfator works by sending high frequency pulses of electric current through the battery causing the sulfate to break from the battery plates and dissolve back to the electrolyte w/c is a mixture of water and sulfuric acid. This ensures a proper balance between the electrolytes, conductivity of the plates, battery resistance and other factors affecting battery performance. For more information regarding desulfators and the principles behind it's operation, you may start from this link:

(https://en.wikipedia.org/wiki/Battery_regenerator)

Now since you have an idea of what is a desulfator is, let me tell you of what happened to my unit just this week.

I've been using this

Infinitum battery desulfator for about two years now and I must say, I'm satisfied with this product. I bought it online from the infinitum store for about $44 including shipping.

Had no battery related problems since I started using this. My old car still cranks very good and the battery maintains a stable charge even after more than two years of use. I'm thinking of posting a review of this product maybe after 3 years or so but then it broke (at this point, I'd claim that it's because of my fault). You'll know the reasons later on.

I've been using this on my new car for about 4 months now. Last weekend, as I was doing a routine checkup under the hood, I noticed that the indicator light is out, meaning, it's not working. So I took it to my workbench to take a closer look.

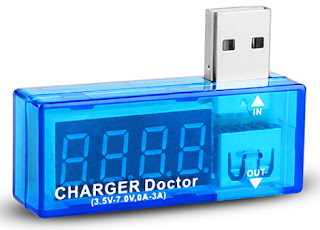

Initial tests confirm that the unit is out cold (It's just a matter of connecting this to suitable a power supply),

still no green light. So at this point, I decided to look inside and see if a repair is possible.

First up is the tear-down. The unit is very well made and is solid in construction (I mean really solid as you'll see later). It is enclosed in an aluminum casing and initial access is only possible on the aluminum covers on the side of the unit.

So I proceed by prying the sides off to take a look of what's inside. My excitement goes right out the window as soon as I'm able to open the cover on one side.

The innards were potted with some kind of epoxy. I think I understand why this has to be done by the manufacturer. Since this product is used with a lead acid battery, a good seal is important to protect the internal components from a corrosive environment. A battery's electrolyte is a strong acid, and gas produced like hydrogen is very reactive as well. Besides, if this will be used in cars, boats or machinery, potting will help secure the components from vibration and other mechanical stress.

I wonder if manufacturers also do this to avoid tampering, reverse engineering and/or possible duplication of their electronics design. I've seen some electronic repair or tear-down that prevents such because of some potted components. Well, at this point, I thought a repair will not be possible.

Since this will now be tear-down, I proceed to perform a total destruction or a 'postmortem' analysis on the unit (and hopefully learn something in the process).

By now, I'm sure of the reason why it broke. First up, I noticed moisture and water accumulation on the unit. There's some form of corrosion already on the LED terminals. Since the copper side of the PCB is not filled with epoxy completely, I see much worse corrosion on the inside where moisture was able to penetrate deeper.

This unit is mounted under the hood of my car as close as possible to the battery.

*Desulfators need the shortest possible wiring to the battery to avoid power loss on the cable and ensure proper delivery of high current pulses to the battery.

It is fitted on the side of the battery near the right side of the engine where some clearance is present between the hood cover and the chassis for engine ventilation. It's not very obvious at first but I can confirm that water is able to get in through this clearance during a heavy rain or a car wash. Since the unit is pretty tight (no screws at all), I thought a little bit of water spill will not do any harm. Maybe if have known earlier that the unit is filled with epoxy, then I'd be much more confident that moisture will not pose any problem. Anyway, so much for the wrong assumptions.

On with the tear-down, I opened the other side and this is how it looks. A solid completely potted block.

What else to do next but try to find another opening. I'm thinking of pounding the unit from one side hoping the innards will come out the other side but I'm having a little bit of thought that maybe the middle part of the block is not completely potted and might be destroyed beyond recognition should I pound it hard enough. To be more 'gentle', I decided to cut the sides of the enclosure with a

Dremel cutting tool. I'm really interested to see the rest of what's inside.

This is how the cut was done from the side of the enclosure ( Dremel cutting tool works like a charm).

The top part of the enclosure came off and...voila!

The inside is a solid block of potting epoxy. There's a section were it seems a portion of a coil or transformer is visible.

At this point, I'm thinking that I cannot go on much further. This potting is so hard that the only way to know what's inside is to break it apart completely which will not make much sense at all.

Prying the sides of the enclosure, the whole block came out and now the bottom part (copper side of the PCB) is visible.

Here, we can now see the extent of the damage caused by water penetration. The upper part of the pcb side is not completely potted and some kind of paper insulation is visible. This made the water penetration much more destructive.

Lifting up the insulator, we can see that water caused severe damage and corrosion to the PCB traces. As we all know, water and electricity usually don't mix very well.

I did some cleanup and saw that some of the copper traces are severely damaged, a portion just lifted off the board. But, a quick continuity test confirms it still is conductive.

With much doubts if cleaning the corrosion would help, I gave it a quick test to see if somehow it will come back to life. And as expected, for the time being, the unit is still out cold. Still looks like a no turning back tear-down at this point so I continued trying to break this thing apart.

Trying to crack this open, I placed it on a vise and cranked very hard. Then comes a different turn of events.

The whole bottom part of the potting came off in one piece, leaving the rest of the PCB and copper traces intact. Apparently, the corrosion caused the potting to crack and and weaken it's adherence on the PCB. Now we can see the whole extent of the water damage. Immediately, I noticed a portion of the PCB which is severely damaged. As this thing came apart, the smell of burnt plastic filled my workbench. This came from a portion on the side of the PCB with big copper traces going to the input / output terminals (right in the center of the picture above).

Continuing with the investigation, we can see that the PCB material was charred and is completely burned.

This maybe due to some shorted circuits created between the aluminum housing (attached to the car's chassis w/c is effectively the negative terminal of the battery) and the PCB trace. Of course, this would not have happened if the water did not cause the corrosion in the first place.

Here you can see the point of contact within aluminum case where the short happened.

Since the burned portion effectively cuts off the PCB trace(and the circuit), at this point, my hopes of this tear-down turning into a repair went through the roof even if I only have access on the PCB side of the board.

After a good cleaning and some reconstructive soldering, this is how it looked like.

Looking at the copper traces, I see a couple of IC's, a transistor and a transformer or some kind of coil. Typical components for a desulfator circuit. Well, I'm not really into trying to reverse engineer this device so I did not pay much attention to decode the components and the circuit design.

After that, I performed a quick test and to my surprise, the unit came back to life.

* The green light is on and the unit is consuming about 20mA of current at 13 volts supply voltage.

But then, this only confirms that the unit is consuming power but is it really sending out those pulses of current or high voltages.

So I hooked it up to my scope and indeed, it is behaving as expected.

*The scope was set to 500us horizontal sweep , 5v/div vertical, peak detect acquisition w/ AC coupling.

Here's a closer view of the DSO trace.

At this point, I'm not very particular on the actual readings since this might be different when connected to an actual battery. The properties of these pulses depends also on the supply voltage and the battery's characteristics. As I've mentioned before, even the length of the connecting wires can affect the actual output pulses.

I'm gonna post updates as soon as I have the final measurements taken from a final installation.

Closer view of a single pulse @ 100ns horizontal sweep.

Closer view of a single pulse @ 100ns horizontal sweep.

But wait, you might be asking what about that red LED?

Well, this gadget features a low voltage shutdown to prevent this unit from continually discharging the battery when this is left connected and the battery is not being recharged for quite a while. The red LED lights up to indicate that the battery voltage is low and the unit is in shutdown mode. To test if this feature is also functional, I just dialed down the power supply slowly until the red LED lights up.

And it did at around 11.4 volts. As you'll notice, the current consumption went to down to 10mA (which is 20mA during normal operation).

And so, since it's working fine again, all that's left is finding a suitable enclosure and re-installing this neat little gadget. Since I'm still considering of installing this on the same location inside the hood of my car, I just need to ensure it is water tight.

I really didn't expect that I will be able to repair this gadget given the circumstances but then I'm still glad I was able to do this.

As always, it was a lot of fun.

Any questions, comments or suggestions? please let me know in the comments section.

If you like this, please let me know by giving me your thumbs up and I will try to upload similar repair and or troubleshooting blogs & videos.

Til next time, bye!

Short video recap available on my youtube channel:

https://youtu.be/qjy5B6ECAz4